| Business Type | Manufacturer, Exporter, Supplier, Retailer, Importer |

| Dimension | 403 x 588 x 444 mm |

| Brand | Fischer |

| Application | Industrial |

| Click to view more | |

Product Details

Protection Class

IP40

Power Consumption

Max. 120 W

Power Supply

AC 115 V or AC 230 V 50 / 60 Hz

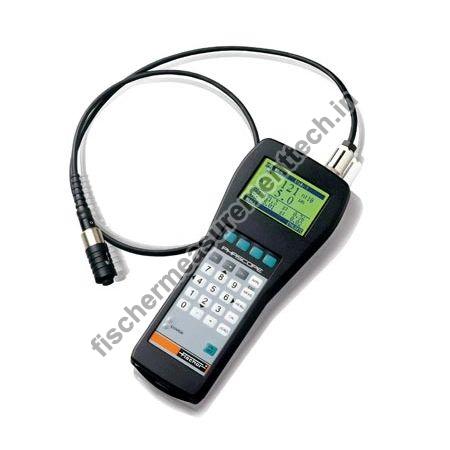

Hand-held instrument for measuring coating thickness on PC Boards and electroplated surfaces. The hand-held PHASCOPE® PMP10 is ideally suited for quality control in the electroplating and printed circuit board (PCB) industries. Because the instrument employs the phase-sensitive eddy current method (ISO 21 968), it allows the measurement of metal coatings on any substrate. A specially designed probe even enables measurements in PCB throughholes.

Applications

- Measuring copper thickness in PCB through-holes, especially on thick PC Boards.

- Measuring coating thickness of nickel on steel

- Measuring zinc or copper on steel â despite rough surfaces and complex surface geometries

- Measuring the thickness of non-ferrous metals on non-ferrous metals, given sufficient difference in conductivity, e.g. copper on brass or bronze

- Measuring the thickness of non-ferrous metals on insulating substrates, such as copper layers on circuit boards.

- Sheet metal processing

- Paint/zinc on iron, e.g. thin EPD coatings

- Paint on aluminium

- Paint on steel

- Brake line tubing

- Wire (mesh and lattice), e.g. shopping trolleys

Instrument features

- DUPLEX measuring mode: display of paint on zinc on iron or paint on aluminium

- DUAL measuring mode: display of total thickness (paint and zinc) on iron or paint on aluminium

- Extensive evaluation and statistics functions

- Outlier control and tolerance monitoring options

- Various languages to choose from

- Battery and/or continuous operation via plug-in charger (included)

- Storage of up to 20,000 readings

- Data transfer via RS232 interface

Looking for "PCB Coating Thickness Measurement Phasoscope" ?

Piece

Explore More Products